Radiographic Testing Film Interpretation (RTFI)

The examination of the finished radiograph should be made under conditions that favor the best visibility of detail combined with a maximum of comfort and a minimum of fatigue for the observer.

Learn more

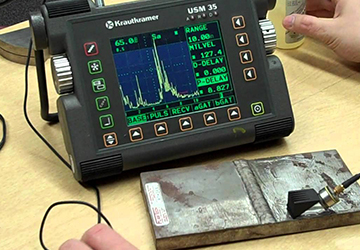

Ultrasonic Testing (UT)

Is a non-destructive test method that utilizes sound waves to detect cracks and defects in parts and materials. It can also be used to determine a material's thickness, such as measuring the wall thickness of a pipe.

Learn more

Phased array Ultrasonic Testing (PAUT)

Is an advanced method of ultrasonic testing and can be used for a multitude of different inspection tasks. ... This technique is used to detect flaws that cannot be easily found with conventional non-destructive testing methods such as radiography and manual ultrasonic testing.

Learn more

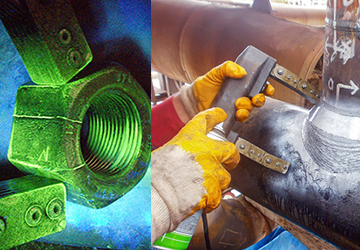

Magnetic Particle Testing(MPT)

Is a non-destructive testing method that can detect surface and subsurface flaws in ferromagnetic materials. Magnetic particle inspection is often carried out to help determine an item's fitness for use or conformity.

Learn more

Dye Penetrant Inspection (DPI)

Is widely used to detect surface breaking flaws. This non-destructive testing technique, also known as liquid penetrant inspection (LPI), is a cost-effective method used to locate surface breaking flaws such as cracks, porosity, laps, seams and other surface discontinuities

Learn more

Positive Material Identification (PMI)

Is a fast and non-destructive testing (NDT) method for verifying the chemical composition of metals and alloys. PMI can be used to verify that supplied materials conform to the proper standards and specifications.

Learn more

Hardness Testing (HT)

Enables you to evaluate the strength, ductility and wear resistance of a material, which can determine whether a material is suitable for the purpose you require. The hardness of a metallic material can be defined as its resistance to plastic deformation caused by a force applied through an indenter.

Learn more

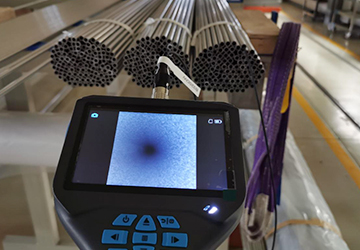

Visual Inspection (VT)

The simplest form, visual inspection is the process of examining a component or piece of equipment using one's naked eye to look for flaws. Optical aids such as illuminators, mirrors, borescopes, etc. Visual inspection is simple and less technologically advanced compared to other methods.

Learn more

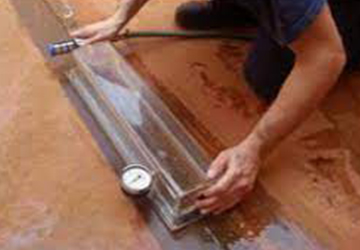

Vacuum Box Testing / Bubble Test

Is used to determine the air-tight integrity of a prevacuum autoclave's chamber and plumbing system. This test exposes the autoclave's plumbing and components to vacuum conditions and measures how much vacuum depth was lost over a given period of time.

Learn more